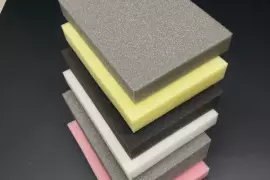

Available Foam Material Types

Atlas Foam Products supplies, fabricates, converts, and manufactures foam products for a wide array of industries and applications for over 50 years. We have become a leader in innovative custom foam and packaging foam solutions in Los Angeles and all of southern California. Our experienced foam product designers use high-quality raw materials to expertly design products accurately and efficiently. As a trusted foam product distributor and manufacturer, we service a wide range of commercial and industrial customers of all markets.

We pride ourselves as having a complete line of foam materials and state-of-the-art foam cutting and fabrication capabilities for all your standard and custom applications and requirements. Choosing the right foam material is a critical step in any successful foam packaging, component, or product. At Atlas Foam Products, we have a deep understanding and years of industry experience with every type of foam material. Contact us before you begin your next foam project. We will help you understand the benefits of each foam material type and then assist you in selecting the foam material that fits your unique needs and best serves your application and industry requirements.

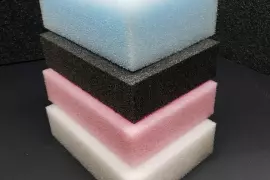

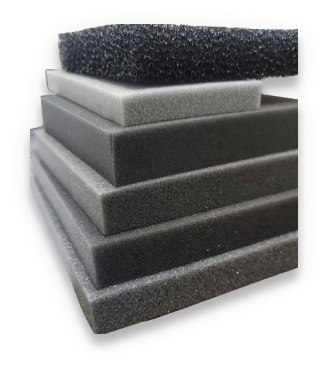

Open-Cell Versus Closed-Cell Foam Materials

Foam material is generally categorized as either an open-cell or closed-cell material because of the makeup of the cell structure and the material itself. Each foam type exhibit similar and unique material properties and different strengths and weaknesses. Because of this, both open-cell and closed-cell foam materials offer advantages to different applications and industries.

Open-Cell Foam Materials

Open-cell foam contains cells or pores that are not completely encapsulated and deliberately left “open.” Thus, the cells resemble little air bubbles that form an interconnected network that is relatively soft and almost sponge-like. While open-cell foam is typically less dense than closed-cell foam, it is softer and more breathable and flexible. This allows it to easily conform to required shapes and enhances its ability to return to its original shape after being compressed.

Open-cell foam is ideal for applications that require vapor, moisture, and air permeability. Also, the pores spaces help trap foreign particles, reduce dust and allergens, and enhance its resistance to mold and mildew growth. Because it requires less raw material to produce it, open-cell foam is a less expensive option than closed-cell foam.

Polyurethane Foam

Polyurethane is a flexible foam material that is used in a diverse range of applications and industries. It offers excellent cushioning, support, comfort, and protection. It provides adequate protection and support and often used for packaging light-weight products. Even after repeated impacts, polyurethane foam is durable enough to maintain its form without losing its original shape. This makes it an ideal foam material for seats, cushions, bedding, and furniture.

We offer the following types of open-cell Polyurethane foam materials:

Closed-Cell Foam Materials

As the name suggests, closed-cell foam is made up of a cell structure that is completely closed. Because the cells are pressed together, this foam material is generally denser and more rigid than open-cell foam. It also exhibits greater dimensional stability, low water and moisture absorption, and a high strength-to-weight ratio.

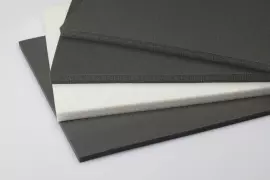

Closed-cell foam deliver excellent performance and protection in both exterior and interior environments. It provides a superior moisture barrier, reduces vapor transmission, and offers excellent resistance to spills and leaks. While easy to process and fabricate, closed-cell materials require more raw materials and are a more expensive option to open-cell foam types.

We offer the following types of closed-cell foam materials:

Specialty Foam Materials

Atlas Foam Products also carries a wide selection of specialty foam materials that are engineered and designed to solver very specific problems. Regardless of your application needs or special requirements, we can identify the right specialty foam material for your next foam project. We have decades of experience working with and fabricating high-quality foam products that deliver the special qualities you need, including anti-static, electrically conductive, breathable, static dissipative, fire retardant, and more.

We offer the following types of specialty foam materials:

- Anti-static Foam

- Conductive Foam

- Flame-retardant Foam

- Rebond Foam

Free Consultation with a Foam Expert

Consult with our engineering staff and design production personnel on any and all cushioning questions. Our experts can help you determine the proper size, and density of material with the most economical production methods.

Have Questions?

Give us a call at 818-837-3626 or fill out the form to send a message to one of our Foam Experts. We proudly provide services to local areas including Los Angeles, San Fernando Valley, Santa Clarita Valley, Simi Valley, Ventura, Oxnard, Orange County, Riverside, San Bernardino, and the Contiguous U.S.